Publication as an International Standard requires approval by at least 75% of. ISO/TS 16949 was prepared by the International Automotive Task Force (IATF),. Third edition. Quality management systems —. Downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing. This International Standard promotes the adoption of a process.

Why TS and Not Just ISO 16949?

The International Organization of Standards (ISO) develops many different types of standards for a variety of industries. Recommendations to ISO for a new standard require a two-thirds majority vote for approval as a Technical Standard (TS) and a three-quarters majority vote to become an ISO standard.

ISO/TS 16949 Requirements and MasterControl Features

Iatf 16949 Manual Free Download

Aaliyah one in a million song download. For each requirement of the ISO/TS 16949 standard, MasterControl software solutions offer a corresponding benefit to meet each standard:

- Clause 4.2.3 Control of Documents: MasterControl Documents automates routing, escalation, approval and delivery of SOPs, policies and other documentation.

- Clause 6.2.2.2 Training: MasterControl Training programs assignment and monitoring of training tasks and grading of online exams and allows sequencing of training courses.

- Clause 7.1.4 Change Control: MasterControl Change Control streamlines the entire procedure for faster turnaround with reports that provide real-time status updates.

- Clause 7.2.3 Customer Communication: MasterControl Customer Complaints simplifies the complaint-handling process and reduces the life cycle from submission to resolution.

- Clause 8.2.1 Internal Audit: MasterControl Audit automates, updates and manages the audit process. It also provides advanced tracking capability throughout the entire audit process.

ISO/TS 16949 Replaced by IATF 16949

In September 2018, ISO/TS 16949:2009 was replaced by IATF 16949:2016. The new certification from the International Automotive Task Force (IATF) provides an interdisciplinary approach that is more focused on risk management, customer satisfaction, leadership and process. One of the biggest changes from ISO to IATF is the requirement for more documentation and documented evidence. Companies with ISO/TS 16949 certifications will have to conduct an audit in order to acquire IATF 16949 certification, which will continue to be aligned with ISO 9001:2015.

ISO/TS 16949 Certification

The following steps should be considered when implementing ISO/TS 16949 to achieve certification:

- Gap analysis (existing system and ISO/TS 16949 requirements)

- Trainings

- Transformation and development of manuals, procedures, operator instructions

- Implementation of procedures

- Suppliers development

- Internal audits

- Registration audit

MasterControl and ISO/TS 16949

MasterControl solutions help you to meet ISO/TS 16949 and IATF 16949 requirements year after year while keeping compliance costs down. The connectivity of MasterControl solutions software gives you the ability to monitor your entire quality management system (QMS) and continuously improve it to ensure that company quality initiatives are enforced across the enterprise.

MasterControl and the FDA

MasterControl and its partner, i4DM, have served as the quality management system (QMS) providers for the U.S. Food and Drug Administration’s (FDA) Office of Regulatory Affairs since 2009. They also serve as QMS providers for the Division of Pharmaceutical Analysis, part of the FDA’s Center for Drug Evaluation and Research (CDER).

Dec 21, 2017 - Travis and Quavo release their long-awaited project. Travis Scott and Quavo have been teasing a collabo album for more than a year. Travis and Quavo have just dropped Huncho Jack, Jack Huncho. Huncho jack jack huncho download itunes. Saint Laurent Mask. Dec 28, 2017 - Huncho Jack, Jack Huncho, 0:41:33. AIFF, ALAC, FLAC. 5, Huncho Jack, 03:19, 44.1/24, Album only. Which Format Should I Download?

Cartography thematic map design 6th edition pdf download free. There are 11 chapters and two Appendices including: Reference systems and Projections, Topographic instruments and Geometry of coordinates, Conventional construction of a topographic map, Design and reproduction of a thematic map, Digital Topographic mapping - GIS, Digital Terrain Models (DTM / DEM), GPS, methods of Photogrammetry, Remote Sensing, new technologies LIDAR, IFSAR, the method of Least Squares adjustment, Description of educational software accompanying the text. The objective that educated people must be 'smarter than the machine' and not to treat the machine as a 'black box' being 'button pushers' has been achieved, through the author's experience in USA and Greece, with relative success by adopting this didactics technique.

ISO/TS 16949 is an ISO technical specification aimed at the development of a quality management system that provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the automotive industry supply chain. It is based on the ISO 9001 standard and the first edition was published in June 1999 as ISO/TS 16949:1999.[1]

It was prepared by the International Automotive Task Force (IATF) and the 'Technical Committee' of ISO. It harmonizes the country-specific regulations of quality Management systems.[2]

About 30 percent of the more than 100 existing automobile manufacturers affiliate the requirements of the norm but especially the large Asian manufacturers have differentiated, own requirements for the quality management systems of their corporate group and their suppliers.[citation needed]

ISO/TS 16949 applies to the design/development, production and, when relevant, installation and servicing of automotive-related products.

The requirements are intended to be applied throughout the supply chain. For the first time vehicle assembly plants will be encouraged to seek ISO/TS 16949 certification.

- 1Historical background

- 4References

Historical background[edit]

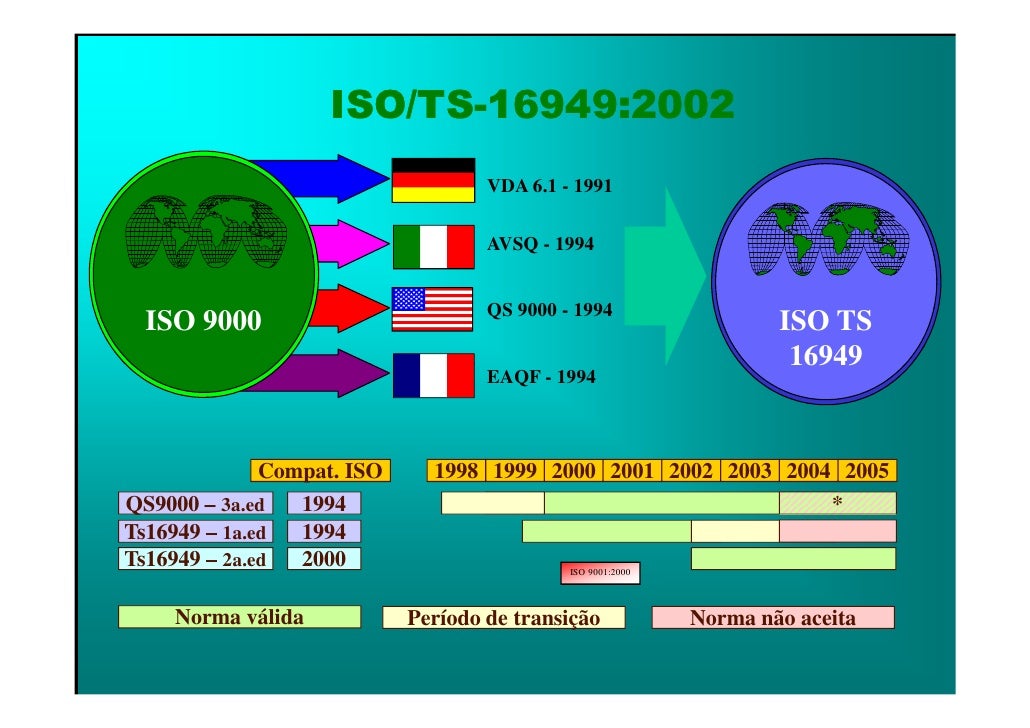

Many suppliers (OEMs) were asked by the car manufacturers to build and certify their quality management system according to the rules and regulations of their own country organizations, such as:

- VDA (Germany)

- AIAG (North America)

- AVSQ (Italy)

- FIEV (France)

- SMMT (UK)

But due to this regulation a supplier needed to provide two different certificates for Daimler and Chrysler (VDA 6.1 for Germany and QS 9000 America), even though the supplier delivered only to a single company. These complexities accelerated the need for harmonization.

Superseded in 2016[edit]

In 2016, the IATF published the IATF 16949:2016, which superseded and replaced the ISO/TS 16949.[3]

Contents of the specification[edit]

The aim of the standard is to improve the system and process quality to increase customer satisfaction, to identify problems and risks in the production process and supply chain, to eliminate their causes and to examine and take corrective and preventive measures for their effectiveness.[4] The focus is not on the discovery, but on the avoidance of errors.The eight main chapters of the standards are:

- Chapters 1-3: Introduction and Preface

- Chapter 4: Quality Management System (general requirements, control of documents and records)

Iso Ts 16949 2016 Pdf

- 4.1 General

- 4.2 Documentation Requirements

- 4.2.1 General

- 4.2.2 Quality Manual

- 4.2.3 Control of documents

- 4.2.3.1 Engineering Specification

- 4.2.4 Control of records

- 4.2.4.1 Records retention

- Chapter 5: Responsibility of the management

- Chapter 6: Management of resources

- Chapter 7: Product realization

- Chapter 8: Measurement, Analysis and Improvement

The process-oriented approach to business processes that is addressed in the ISO 9001:2008 is the base of the standard. It looks at the business processes in a process environment in which there are interactions and interfaces that need to be recognized, mapped and controlled by the quality management system. Additionally the gateways to the exterior (to sub-suppliers, customers and to remote locations) are defined. The Standard distinguishes between customer-oriented processes, supporting processes and management processes. This process-oriented approach is intended to improve the overview of the whole process. This is not an isolated process, but a combination of all interacting business processes which affect the quality performance of a firm.

Ts 16949 Pdf Free

A key requirement of ISO/TS 16949:2009 is the fulfillment of customer-specific requirements, set up by the automotive manufacturer in addition to the quality management system of their suppliers. This may have decisively contributed to the worldwide recognition of the TS by many manufacturers.

Certification[edit]

Ts 16949 Manual Free Download

The ISO/TS 16949 can be applied throughout the supply chain in the automotive industry. Certification takes place on the basis of the certification rules issued by the International Automotive Task Force (IATF). The certificate is valid for three years and must be confirmed annually (as a minimum) by an IATF certified auditor (3rd Party Auditor) of an IATF recognized certification body. Re-certification is required at the expiry of the three-year period. Certification pursuant to ISO/TS 16949 is intended to build up or enforce the confidence of a (potential) customer towards the system and process quality of a (potential) supplier. Today, a supplier without a valid certificate has little chance of supplying a Tier 1 supplier and certainly no chance of supplying a car manufacturer with standard parts, if indeed that OEM is a participating member of the IATF (most Japan OEM are members of JAMA and not members of the IATF) .[5]

Certification bodies include:

- TÜV Rheinland (Germany)

- BSI Group (UK)

- Bureau Veritas (France)

- DNV GL (Norway)

- DQS (Germany)

- EAGLE Certification Group (USA)

- IFCE (NORTHERN IRELAND)

- LRQA (UK)

- SAI Global (Australia)

- SGS S.A. (Switzerland)

- TÜV NORD (Germany)

- TÜV SÜD (Germany)

References[edit]

- ^[1]

- ^Cassel, Michael (2007). ISO/TS 16949 QM in der Automobilindustrie umsetzen. Germany: Carl Hanser Verlag. p. 1.

- ^'IATF 16949:2016'. AIAG. 2016-10-03. Retrieved 2016-11-11.

- ^Kartha, C.P. (2004). 'A comparison of ISO 9000:2000 quality system standards, QS9000, ISO/TS 16949 and Baldrige criteria'. The TQM Magazine Volume 16. Emerald Group Publishing Limited. Number 5: 336.

- ^<http://www.jama-english.jp/>Daimler (2002). 'Global supplier magazine'. 4th quarter. Daimler: 17.

External links[edit]

- ISO/TS 16949:2009 Quality management systems—Particular requirements for the application of ISO 9001:2008 for automotive production and relevant service part organizations